Bessemer Steel Process: The Great Invention That Shaped the Steel Industry

BlogDate: 02-05-2024 by: Nhu Quynh

The Bessemer steel process was first invented by the British scientist Henry Bessemer. His invention helped steel materials become popular and widely used in many industrial fields, becoming an indispensable part of human life.

It is the first lever for future modern steelmaking processes, but not everyone clearly understands this steelmaking process. The article below by MRS Steel will help you better understand the Bessemer process.

Bessemer Convertor at Kelham Island Museum, Sheffield

What is the Bessemer process?

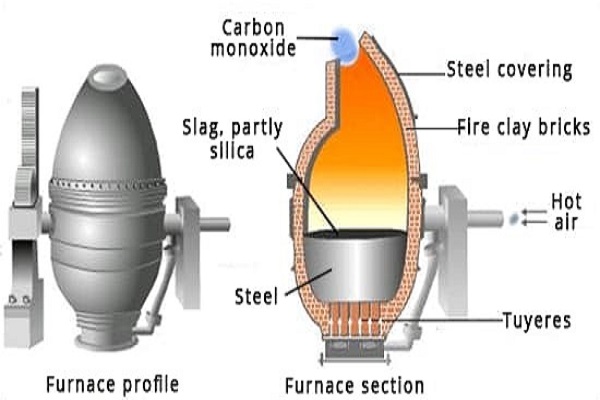

Bessemer steel process is a method of steel production invented in the 19th century by an England inventor. This is a steel production method in which air is blown into a furnace at about 1250°C to burn off impurities and iron, thereby creating steel products. The Bessemer process is also named after its inventor and is the forerunner of today's modern steel production process.

Before its launch, the Bessemer steel process conducted experiments for 2 years until the main idea was drawn. However, during the research process, many metallurgists were still skeptical about the theoretical foundations and were only truly convinced when they saw the process of converting iron into steel. The Bessemer process is shaped like an egg with an inner lining of clay and an outer layer of hardened steel, at the top of which there is a small hole to blow air into the furnace.

Who invented the Bessemer steel process?

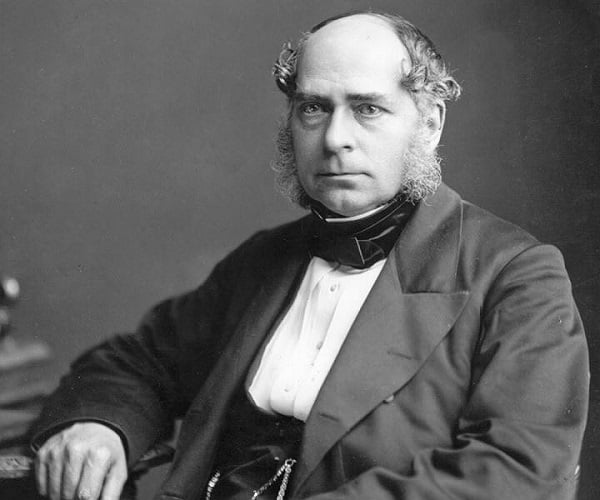

The Bessemer process is an invention of Henry Bessemer’s. He was born in 1813 and passed away in 1898. During his lifetime, he had more than 100 inventions, the most prominent of which was the invention of the steelmaking method that bears his name, the Bessemer method.

Henry Bessemer - Inventor of the Bessemer process

Although this method is no longer used in steel production today, at the time of its invention, it was an important method for the industry because it lowered the cost of steel, thereby helping steel production. replace some other materials, especially for the manufacture of military weapons.

History of the Bessemer steel process

When was the Bessemer process invented? What is the history of this process? Find out with MRS Steel below!

Henry Bessemer's interest stemmed from the scarcity of steel during the war in 1853. At that time, steel was only used to make small objects such as knives, scissors, springs, and similar things. At this time, Bessemer began to find a way to make steel from brittle iron that contained a significant amount of carbon. In his initial experiments, he used a reverberatory furnace capable of isolating iron metal from burning fuel; however, at this time, the furnace did not meet his needs.

Bessemer redesigned the reactor to suit the needs of steel making. After countless experiments, he created the new egg-shaped Bessemer steel process with the ability to produce from 5 to 20 tons of steel at a time. Bessemer's steel making process was patented in 1855 and existed for more than 100 years before being replaced by today's modern steel making furnaces.

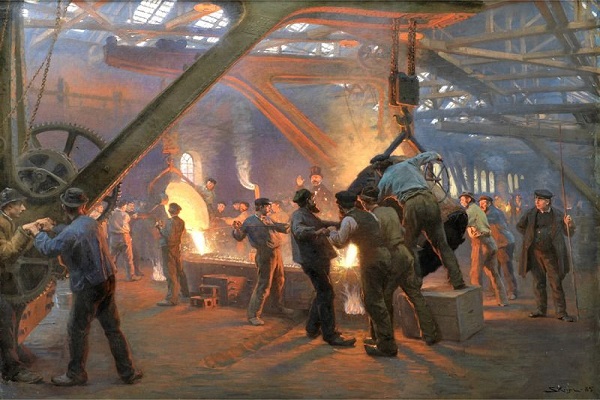

The bessemer process is operated at the steel mill

The Bessemer steel process is considered a breakthrough method in the field of steel production because it allows mass production of steel. Besides, it also promotes the rapid growth of the construction, transportation, and manufacturing industries. The availability of affordable steel played a key role in the construction of bridges and railways, paving the way for significant advances in industrialization and infrastructure.

How does the Bessemer process work?

With this discovery, other steelmakers began to perfect the process, eventually discovering how to use air blowing to help preserve carbon content while completely removing impurities. Ultimately, this process evolved into the highly economical mass production method of steel that we still use today.

Bessemer steel process is considered an industrial process for mass steel production at low cost. Before developing into today's blast furnaces, the Bessemer process worked by adding iron to a molten cast iron mixture cooked at high temperatures. Air, then blown into the furnace along with the molten iron, provides oxygen to react with the impurities (these impurities include silicon, manganese, and carbon), turning them into oxides that can be separated as slag. The heat generated during the steelmaking process will increase the temperature to prevent the product from freezing during the heat treatment process. After finishing the heat treatment, the finished steel product has a high hardness and ductility.

Structural diagram of the Bessemer process

The Bessemer process helped revolutionize the steel industry

The Bessemer steel process is considered a breakthrough method in the field of steel production. Previously, steel production was an expensive process, which limited its production and use. The Bessemer process opened new doors for the steel industry, providing the foundation for future steel production technologies.

Bessemer steel process allows low-cost mass production of steel. It fueled the rapid growth of the construction, transportation, and manufacturing industries. The availability of steel at affordable prices played a pivotal role in the construction of bridges, railways, skyscrapers and machinery, changing the face of modern civilization.

Surely, the above article by MRS Steel has helped you better understand the Bessemer steel process. Although, with the continuous development of the steel industry, the Bessemer process no longer has a place in the production of modern construction materials, it has laid the foundation for the development of the steel industry today.