All about tensile strength of mild steel that you need to know

BlogDate: 29-04-2024 by: Ngan Le

Mild steel is a well-known type of steel in machining and manufacturing fields due to its ductile nature and excellent corrosion resistance. Tensile strength of mild steel is one of the most important specifications to comprehensively analyze its power. Moreover, manufacturers often rely on yield strength, and elongation percentage to evaluate quality and performance.

So, what significance does the mild steel tensile strength hold in demonstrating the power of this type of steel? Let's define the concepts in the following article together with MRS Steel!

The tensile strength of mild steel is the crucial technical parameter determining hardness

What is mild steel and some important applications

Mild steel is a type of low-carbon carbon steel with typically less than 0.25% carbon content, primarily composed of iron and carbon along with residual compounds including alloying elements such as manganese, silicon, and sulfur. The combination of these elements has helped enhance mechanical properties through a balance of tensile strength and yield strength in mild steel.

Today, mild steel finds extensive usage across various industries including construction, automotive manufacturing, machining, household appliance production, and numerous other applications. Due to its low carbon content, mild steel is highly versatile in cutting, welding, or machining activities, making it the most commonly used type of steel in manufacturing and fabrication.

Definition and role about tensile strength of mild steel

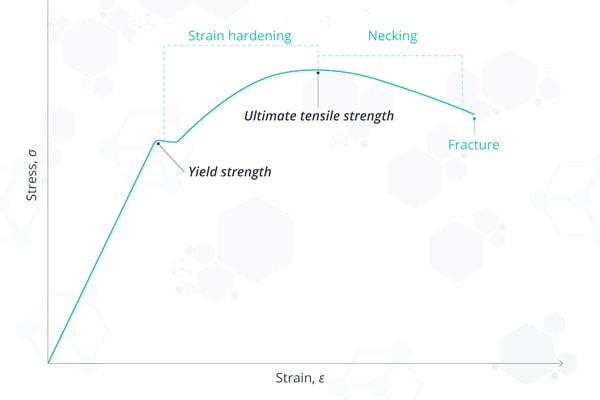

The tensile strength in mild steel is a parameter reflecting the maximum load-bearing capacity of the steel without fracturing, although the steel product will undergo permanent deformation due to the extremely large applied force. To evaluate the tensile strength of mild steel, a gradually increasing force is typically applied to both ends of the steel sample until it fractures or breaks. At the point where the applied force reaches a certain value causing the steel product to fracture, manufacturers record the tensile strength of the steel at this point.

Tensile strength is the value that records the force required to fracture steel

The results are measured in pressure units, usually pounds per square inch (psi) or megapascals (MPa). High tensile strength is often associated with good tensile load-bearing capacity, making the steel suitable for applications requiring strength and high durability.

Analyze technical specifications about tensile strength of mild steel

Evaluating the mild steel tensile strength is highly important, as it is a determining factor in assessing whether the hardness of mild steel is suitable for the application requirements. For applications requiring flexibility in processing, selecting mild steel with appropriate tensile strength is crucial to ensure efficiency in achieving the desired goals.

The greater the tensile strength, the higher the hardness of the steel, because mild steel is relatively ductile compared to other carbon steels, so the tensile strength of this type of steel usually ranges around 400 MPa. In addition to being measured in MPa, the unit of measurement for the mild steel tensile strength can also be expressed in various other units such as Newtons. In Newtons, approximately 485N/mm of force would be required to fracture this steel bar, equivalent to placing a mass of 4200 kg per cm on an object.

If the steel have high tensile strength meaning it has a good hardness

Another important index related to tensile strength is the term "ultimate strength of mild steel," which typically refers to the maximum tensile strength of mild steel, meaning the maximum tension it can withstand before failure or fracture. For mild steel, the ultimate tensile strength usually ranges from about 400 MPa (58,000 psi) to 550 MPa (80,000 psi). Ultimate strength is often a crucial indicator in evaluating the maximum load-bearing capacity of mild steel to determine safety in various applications.

Others properties affecting to mild steel hardness

In addition to tensile strength, manufacturers also rely on several other important indices to create a comprehensive assessment of the strength of mild steel, including yield strength, elongation ratio, mild steel density, and ultimate strength of mild steel.

Mild steel yield point/yield stress

The mild steel yield point is the maximum force that the steel can withstand before it begins to undergo permanent deformation. To determine the yield stress of mild steel, manufacturers apply force to both ends of the steel until it reaches a certain value sufficient to cause the steel to begin deforming without being able to return to its original shape. At this point of onset, they record the yield strength value to serve the assessment of the load-bearing capacity and mild steel hardness.

By definition, the yield strength index of mild steel will be lower than the tensile strength of mild steel because the force applied to the steel is only sufficient to cause deformation without reaching the breaking point. According to various measurement documents, the average yield strength of mild steel is typically recorded around 250 MPa, which, when converted to Newton units, is approximately 345 N/mm². This means that to induce permanent deformation in a mild steel sample, a pulling force of about 345N is required.

Beside the tensile strength, manufacturers can rely on yield stress to evaluate power of steel

Mild steel elongation

Mild steel elongation is a measurement of the ability of mild steel to stretch from the point of initial deformation until it completely fractures, often expressed as a percentage ratio. By formula, mild steel elongation is calculated as the ratio between the tensile strength and the yield strength of mild steel.

When evaluating the ductility of mild steel, a higher percentage elongation indicates higher ductility, as the elongation value is directly proportional to the tensile strength, demonstrating that a considerable force is required to fracture the steel. Since mild steel falls into the category of steel with relatively low carbon content, mild steel elongation typically reaches a minimum of 20%. This ideal ratio has made mild steel suitable for various manufacturing and fabrication applications.

Mild steel density

Steel density is a measurement of the mass of the material per unit volume, often expressed in units such as g/cm or kg/m. Mild steel, due to its low carbon content of about 0.25%, typically has a density ranging from 7.75 to 8.05 g/cm³. However, specific values may vary depending on the specific chemical composition of mild steel and other factors such as manufacturing processes.

MRS Steel - The reputable mild steel supplier for your project

In summary, the tensile strength of mild steel is an extremely important indicator that helps manufacturers and contractors assess the mechanical properties and load-bearing capacity of this material. When combined with other indices such as mild steel yield point, elongation ratio, and ultimate strength of mild steel, manufacturers as well as project owners can evaluate and select suitable materials for specific applications.

Analyzing steel specifications is crucial for purchasers before transacting steel

Similarly, choosing a reputable steel supplier is equally important in quality control and ensuring that the technical specifications of the steel meet the project requirements. With years of experience in the steel industry and extensive relationships with Vietnamese steel mills, MRS Steel can provide optimal solutions in terms of both time and cost for customers, especially for importers. Our supply of mild steel products comes from clearly identified sources, meeting strict standards for tensile strength, yield strength, coating thickness, and more.

If you need to reference comprehensive price lists and mechanical properties charts including tensile strength of mild steel and other steel products, please MRS Steel via Email: vanloc@mrssteel.com.vn or Whatsapp:+84 76 911 2358!