Some Important Effects of PPGI/PPGL In The K Span Roofing System

BlogDate: 05-01-2024 by: Ngan Le

K Span is known as a new anti-leak solution for buildings thanks to the steel material PPGI/PPGL in the K Span roofing system helps eliminate the risk of water leakage for the building. Moreover, the durability in them also supports the system becoming sustainable to inclement weather as well as providing flexibility in disassembly and relocation.

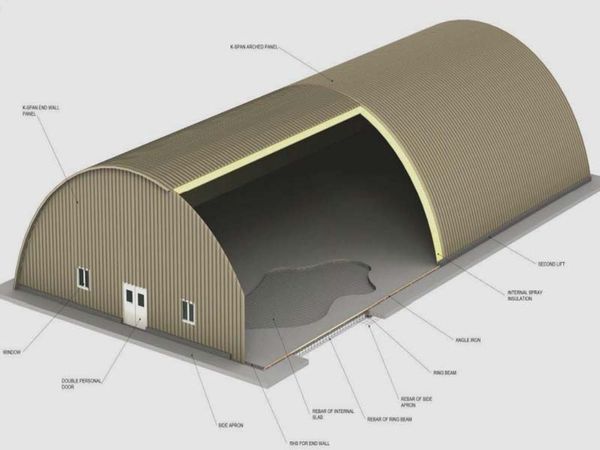

Definition K Span system and its application

K Span is the typical name for the dome structure in construction, these domes are manufactured by the forming equipment that makes them reach their full curvature and then the manufacturer will deliver them to the construction site. The entire K Span is a combination of individual pieces of corrugated iron that are connected together by a specialized jointing system, so that the pieces are tightly linked without the need for screws. Normally, the main raw material for making up corrugated iron pieces in K Span is galvanized steel or pre-painted galvanized/galvalume steel (PPGI/PPGL).

The K Span system is used a lot in the field of construction, many businesses often apply them to make roofs for civil buildings, houses, barns in agriculture, in addition they can be installed as a hangar or entertainment infrastructure,...

Important effects of PPGI/PPGL in the K Span roofing system

Aesthetics and durability are one of the outstanding advantages of pre-painted galvanized/galvalume steel. Therefore, the application of PPGI/PPGL in the K Span roofing system has brought a series of beneficial values to the project.

Simple construction for contractor

Similar to pre-engineered steel buildings, K Span owns a simple construction structure when they are an overall combination of PPGI/PPGL pieces linked through a joint system. The K Span foundation is built on an extended concrete strip surrounding the building, so the contractor will not need to drive fixed piles or beams during construction.

In addition, the main structural components of K Span come from PPGI/PPGI steel, which significantly reduces the weight of the construction compared to traditional brick materials. Thanks to its light weight as well as the simplicity in installing, a K Span system can be set up in almost all soil conditions while still ensuring good stability.

Flexibility in design with PPGI/PPGL in the K Span roofing system

The K Span dome is a combination of a series of coated steel linked together and they are divided according to each span. Thanks to this flexibility, the contractor can arbitrarily change the length of the roofing as desired as they can be dismantled in individual spans. If the building is built with traditional bricks, when the contractor wants to shorten or dismantle it, it will affect the entire structure.

Shorten the time for completing project

K Span is considered a system to help improve the construction process quickly because the main structural components are steel and often steel will be produced directly at the factory. After the factory has done the material as required, these parts are moved directly to the construction site, which inadvertently saves the contractor a lot of time during the building process.

According to average statistics, a construction team with a number of 10 - 20 people can complete a whole installation of 500m2 per day for a K Span system by assembling the parts together accordingly. Compared with traditional construction methods, construction crews often have to spend more time in mixing mortar and disposing cement.

Eliminate the risk of water leakage

In the past, traditional roofs made of mortar or bricks would be prone to leaks because of long standing water absorption. It can be seen that steel is a material that helps to resolve this situation because steel is metal in nature, so it will not absorb liquids. Possessing a K Span dome system will help users feel more secure about waterproofing.

In addition, during the production process, the PPGI/PPGL in the K Span roofing system don't create any holes in the surface, there is no chance for rainwater to enter. Tthe curvature of the dome is a great design that provides good drainage when it rains or in snowy environments.

High tolerance in the inclement weather

The applications of steel in construction, especially the PPGI/PPGL in K Span roofing system is often added with galvanized layers to resist scratches as well as increase durability, prevent oxidizing agents due to chemical reaction by zinc. A project with the K Span system will require less frequent maintenance, thereby making conditions for contractors to save on periodic maintenance costs as well as limiting unwanted cost in repair during the process of using.

Eco-friendly recycling

Construction steel is considered a useful material when it can be recycled and reused consecutively throughout its life cycle without being affected by the internal structure. After a long time of use, the contractor can choose to disassemble the pieces of PPGI/PPGL in the K Span roofing system to manufacture other applications.

Choose a reputable company to provide PPGI/PPGL in K Span roofing system

Climate change is becoming more obviously forthcoming such as abnormal sunshine and rain as well as high humidity, which directly affects construction works. Therefore, choosing a quality material for your construction project will be the right choice to gain long-term efficiency to the contractors.

Understanding the needs of customers, MRS Steel is here to help you find solutions in choosing quality PPGI/PPGL steel materials that come directly from large manufacturers in Vietnam. All our PPGI/PPGL steel products are certified for clear origin, thereby helping you to be more secure in the trading process between the two countries.

If you want to find out information about PPGI/PPGL steel as well as check product price information from manufacturers, please contact Whatsapp:+84 76 911 2358 or email vanloc@mrssteel. com.vn