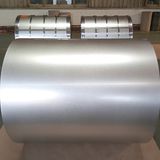

Product Description

In Vietnam, Cold-rolled coil is essentially hot-rolled coil (HRC) that has undergone many processes by being cooled down and then rolled repeatedly to get exact dimensions and better surface qualities. The cold-rolled coil production process goes through many steps, including pickling, cold rolling, and softening, ensuring that it meets the standards of developed countries in the world, such as Japan, the US, France, etc. Modern technology lines from famous brands such as Tenova and Danieli, placed continuously, represent the best thickness and flat surface requirements.