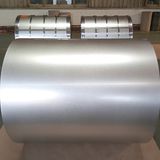

Product Description

The galvalume steel coil - GL has also called aluzinc steel coil is produced by hot dipping process with the dip is 55% aluminum, 43.4% zinc and 1.6% silicon at 600°C. It is a combination of the advantages of high durability of aluminum and the electrochemical protection of zinc. Galvalume steel is primarily utilized in the construction, automobile, metallurgy, electric equipment, and other industries. Modern technology lines from famous brands such as Tenova and Danieli.