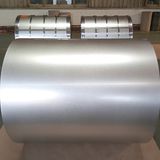

Product Description

In Vietnam, HRPO is carbon steel formed and removed through the process in an acidic solution. To prevent surface rust from forming after this process, hot rolled steel is coated with oil. The hot rolled pickled & oiled production technology in Vietnam was designed and installed by famous brands such as Tenova and Danieli Group - Italy.