Product Description

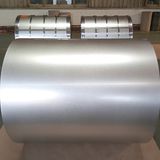

In Vietnam, a wire rod is a hot-rolled wire which is made of carbon steel, aluminum, and copper. Although it has a variety of shapes, it is mostly rolled round, and all steel wire rods are formed into the coils without any break.

Wire rod has a number of applications, including tie wire, mesh, fencing, shelving, shopping carts, wire hangers, and nails. In addition, wire drawn from the rod can be galvanized, plated, and painted.