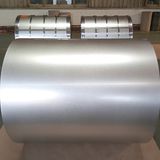

Product Description

In Vietnam, hot rolled steel coil is one of the most popular steel today because of its low cost, high strength, and high load capacity. Hot rolled coil has good heat resistance, which is widely used in the industrial and civil sectors. Hot rolled coil production technology in Vietnam was designed and installed by Danieli Group - Italy considered one of the most advanced technology lines in the world with the name QSP (Quality Strip Production).