The Basic Steps Of The Steel Refining Process

BlogDate: 26-02-2024 by: Nhu Quynh

As a material used in most fields, the steel refining process is of great interest. Join MRS Steel to learn more about the steel refining process in the article below!

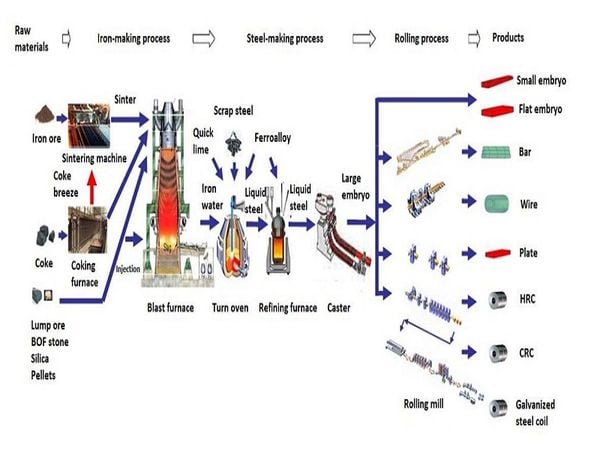

1. Iron Ore Processing: The First Step in the Steel Refining Process

The first stage in the steel refining process is to process iron ore and other metal components to make steel. Iron ore includes a lot of minerals, the processing of which will help remove impurities to obtain the main ones.

Usually, iron ore will be mined in mines in areas with high mineral potential. When put into the kiln, iron ore will be added to other additives such as limestone, coal,...

2. Create a stream of molten steel

After being processed, the steel refining process begins with the introduction of iron ore from the top of the blast furnace, hot gas is blown from the bottom. After being heated at 2000°C, the iron ore will transform into molten steel. During this period, steel usually appears as black steel. Black steel hides carbon, sulfur, silicon as well as many other impurities.

After obtaining the finished product, the steel will be directed to the smelters. At this time, the molten steel is processed, removing the remaining impurities during the heating process. From there, creating a correlation between chemical components in the steel refining process.

3. The next fuel casting

The finished steel of stage 2 is sent to the billet furnace; after being cast, there will be three basic types of billets:

- Bar workpiece: workpiece with a cross section of 100x100 or 125x125, length 6-9-12m. Usually used for rolling or pulling steel coils as well as rebar steel.

- Slab: Usually use rolled-out hot-rolled steel coil, hot-rolled steel plate, cold-rolled steel coil or shaped steel.

- Bloom billet : Used to replace bar or slab workpieces.

In the process of steel refining, after being cast, the workpiece is in two states: hot and cold. In particular, the hot state will be maintained at a high temperature and then taken to the hot rolling place. On the contrary, if it is in a cold state, the billet is transferred to other factories, reheated and then transferred to the rolling process to form the product.

4. Finished products of steel refining process: Hot rolled coil and cold rolled coil

In the steel refining process, at the 4th stage, billets are sent to factories to roll out different construction steel products:

- Bringing a billet into the steel plate factory to roll out cast steel plates.

- Put the billet into the hot-rolled coil factory, and the billet will be rolled into a hot-rolled coil.

- Bringing billets to the section steel mill to roll out rail products, U, V, I, H and bar steel products.

- Bringing billets to steel mills to roll out smooth construction coils.

If you want to roll out a cold-rolled coil, the coil temperature will be lowered to an appropriate level. Then pass through the rust removal line and proceed to roll with the required thickness and size. At this time, the cold-rolled products will have a brighter, more glossy and harder surface.

5. Galvanized steel coil and steel pipe

After the steel refining process, the cold-rolled steel obtained in stage 4 will undergo galvanizing to finish the coil surface. The zinc coating protects the steel against corrosion and increases the life of the product.

Galvanized steel coil is the raw material for the production of steel pipes. In addition to steel pipes, galvanized steel coils are also used to produce Square Steel Pipes, Steel Rectangular Pipe,... with diverse designs and sizes.

Above is the steel refining process made from ore that is applied in most factories. If you want to buy steel products, please contact us HERE.