Importing high-quality galvanized steel coil from Vietnam

BlogDate: 26-01-2024 by: Ngoc Cam

Besides aluminum-coated coils, galvanized steel coils are also widely used materials in many fields. Have you fully understood the characteristics, pros and cons of galvanized steel coils and how the galvanizing process takes place?

1. What is Galvanized Steel Coil?

Galvanized steel coil is a material that is coated with an outer layer of zinc to protect the product from the effects of the surrounding environment such as temperature, humidity, air,... Thereby, limiting the possibility of rust , anti-oxidation and corrosion to increase strength and life span of coils.

2. Methods of galvanizing steel

Currently, there are 3 most commonly used galvanizing methods: cold galvanizing, hot -dipping galvanizing and electro galvanizing.

2.1. Cold galvanizing method

Cold galvanizing is a method of coating a layer of liquid zinc on the surface of the product at room temperature and then putting it through a cold galvanizing process. Here, the mill uses compressed air to blow a liquid solution to form a beam of zinc particles that shoots onto the metal surface. In the solution, there are additives to help the coating adhere firmly to the metal surface and harden in a short time. Cold galvanizing technology helps to improve the corrosion resistance of metal, so it is the best solution for galvanizing metal materials on site.

2.2 Hot dip galvanizing method

Hot-dip galvanizing is the most popular coating technology today, capable of effectively protecting coils from the effects of the environment. This process starts from dipping the product into a molten solution to form a strong, non-flaking base and a smooth, highly aesthetic product surface.

2.3. Electrolytic galvanizing method

Electrolytic galvanizing is a method of electrocoating that forms a thin layer of metal on the surface of coil for the purpose of preventing metal corrosion, increasing electrical conductivity, size and hardness. In fact, the electrolytic galvanizing method is used for steel products such as water pipes, railways, outdoor equipment, bearing equipment, machine parts,...

3. Standard galvanizing process

There are 3 methods of galvanizing steel, but hot-dip galvanizing is still the most commonly used method in Vietnamese factories with the following standard implementation process:

Step 1: Metal surface treatment

Steel made from iron ore or recycled steel also contains many impurities, dirt and oil that reduce the ability to adhere to the coating layer. Therefore, the material needs to be soaked in the degreasing solution for 10 - 15 minutes and transferred to a solution of hydrogen chloride concentration of 8 - 15% to remove rust.

Step 2: Embed Soldering flux

After the steel is cleaned, it has dipped into the flux for about 3 - 20 seconds at normal temperature to completely remove the oxide and iron ions on the surface of the product. This is also the step that creates a coating that protects the steel from oxidation.

Step 3: Hot dipped galvanized

Steel will be completely immersed in the galvanizing bath at the melting temperature (454 - 465 degrees Celsius) to create a layer of zinc coating on the surface. After completing the hot dipping process, performing slag scraping on the surface combined with vibration to remove excess zinc, the product will be coated with a layer of chromate to protect the surface comprehensively.

Step 4: Cool down and check quality

In order for the surface of the galvanized steel coil to be bright and beautiful, the product is cooled by an overflow bath. Experts observe and calculate the thickness of the coating by using specialized gauges to ensure that the finished product meets the specifications and requirements of the customer.

4. Pros and cons of galvanized steel coil

Low cost

The production cost of galvanized steel coil is much lower than other surface protection coating methods, so it is the first choice for large-scale construction projects.

Durable

The zinc coating protects the coil from rust, environmental corrosion and chemical reactions of the inner steel components. According to research, galvanized steel coil has high durability, using life up to 50 years in ideal conditions and from 20-25 years in harsh conditions such as industrial zones, coastal areas,...

Aesthetics

Compared with conventional steel products, galvanized steel coils have a shiny, smooth surface and are easily coated with high-grade color paint to increase aesthetics.

Reduce maintenance costs

Galvanized steel products have high durability, long service life, so it does not cost a lot of maintenance and regular maintenance during use.

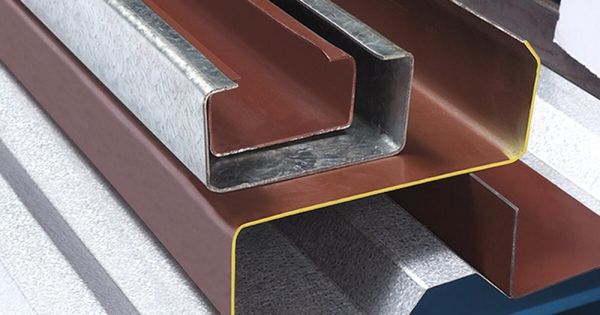

5. Application of galvanized steel

Galvanized steel possesses high strength, good bearing capacity, is a familiar material in popular applications including:

Deck floor application to replace floor formwork

Ventilation ducts for apartments, high-rise buildings, shopping centers, factories, etc.

Producing purlin

Producing all kinds of steel pipes, water supply and drainage pipes, oil and gas pipelines, vehicle accessories,...

Producing household appliances, furniture

…

6. Vietnam's export strength of galvanized steel coil

With investment in infrastructure, modern equipment and strictly selected raw materials, Vietnam galvanized steel coil mills provide product lines with thicknesses from 1.5 to 3.0mm, coating degree Z275 - Z350, strength up to G450.

FDI projects especially favor these types of galvanized steel because of their durability. high quality and good resistance to environmental conditions, so the life of the works can be up to 50 years.

In addition, galvanized steel coils also meet many international standards such as JIS G3302 of Japan, BS EN 10346 of Europe, AS 1397, ASTM A792 of the United States, conquering many difficult export markets such as the EU, the United States, Korea and Southeast Asia,... This is the result of the factory synchronizing production lines imported from the world's most advanced metallurgical and equipment corporations such as Danieli, Tenova and the G7.

MRS Steel is one of the exporters of quality galvanized steel, committed to international standards and specifications from customers. For any specific advice and quotation, please contact MRS Steel via Whatsapp: +84 76 911 2358 for 24/7 support.