The Role of Steel in Construction

BlogDate: 02-02-2024 by: Ngoc Cam

Construction steel is one of the largest steel-using industries, accounting for more than 50% of the world's steel demand. Steel is widely used in all constructions such as buildings, car-parks, schools, hospitals, skyscrapers,... According to a report by the United Nations, it is expected that the world population in 2050 will increase to 9.7 billion people, leading to a dizzying increase in the demand for construction works. In this article, we will learn more deeply about the role of steel in today's construction.

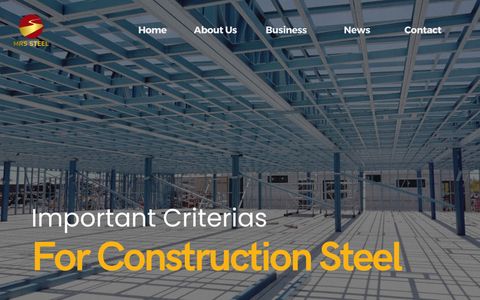

1. What is Construction Steel?

Construction steel is a type of steel used in the assembly and construction process, with many outstanding properties such as high strength, large load capacity, contributing to the solidity of the building.

However, not all types of steel meet the requirements for application in the construction process. Steel must ensure the elements of hardness, strength, weldability and no warping. It is these properties that create the role of steel in construction that no other material can replace.

2. What fields of steel are used?

For buildings

Structural steel accounts for 25% of the steel used in buildings, creating a strong frame on site. Reinforcement bars add tensile strength and stiffness to concrete, which is the primary building material for deep foundations and basements.

Steel sheet is also the main material of cladding products such as roofing, purlins, insulation panels,… Non-structural steels are also found in heating and cooling equipment applications and duct insulation products. In addition, rails, stairs, shelves,... are also made of steel.

For infrastructure

In modern construction, steel is used mostly in projects of bridges and roads, airports, harbors, railway systems, fuel charging stations,... Rebar, sections and plates steel account for 60% of the steel used in these applications. High strength steel has the advantages of durability, heat resistance, fire resistance, good corrosion resistance and rust resistance, making it the main used steel in the pipeline systems of heat, oil, gas, ... in drilling rigs, offshore oil, thermal, nuclear and hydroelectric power plants.

3. Importance of steel in construction

Construction steel is most used to make pillar frames, solid foundations for construction works because of its high strength.

Flexible applicability

Steel is made from many metals that are combined together in certain proportions to determine the characteristics of the finished steel. Therefore, construction steel has many different designs, sizes and properties, so it can be applied flexibly in life, suitable for all project requirements.

Ensure aesthetics

Today, construction works not only require quality but also focus on external appearance. Steel is a material that can meet both of the above criteria thanks to a professional processing and shaping process such as rust removal, oil coating, zinc plating, high-grade color coating,..

Cost savings

Steel accounts for about 23-33% of construction costs, with rough construction apartment buildings can range from 29-30%. Customers choose steel as the primary material in construction because of its availability, ease of access and optimal cost compared to many materials with similar properties. In addition, steel has durability, good weather resistance, so life expectancy is higher, so you do not need to regularly check and maintain it.

Environmentally friendly

As the demand for buildings and infrastructure continues to increase sharply because of the population explosion, reducing natural resource consumption and emissions is the most practical solution to protect the environment. Steel is a material with very good recyclability, easy to handle, remove impurities from scrap steel to create products with quality equivalent to steel produced from iron ore. Steel manufacturers are implementing environmentally friendly construction projects, saving weight and low carbon emissions.

4. Contact to import genuine Vietnamese construction steel

According to statistics of the World Steel Organization, Vietnam ranked 13th in the list of countries with the largest steel production in the world and 14th in steel export output with 11.2 million tons. The signing of the Free Trade Agreement between Vietnam and the EU and the Regional Comprehensive Economic Partnership (RCEP) has helped steel imported from Vietnam enjoy many incentives in terms of tax rates and anti-dumping duties.

Thanks to closed-loop production technology from wire ore and advanced equipment systems imported from Tenova, Danieli and G7 groups, Vietnam's construction steel is always appreciated for its quality. The impurities in the steel are thoroughly cleaned and there are almost no harmful elements left. All production stages are highly automated, meeting strict standards of Vietnam, the USA, the UK,... and strictly controlled by ISO 9001:2015 quality management system.

Construction steel has high applicability in life because of its benefits and importance that no other material can replace. If customers want to learn about the construction steel market and import high quality steel from Vietnam, please contact MRS Steel via Whatsapp: +84 76 911 2358 for detailed advice.